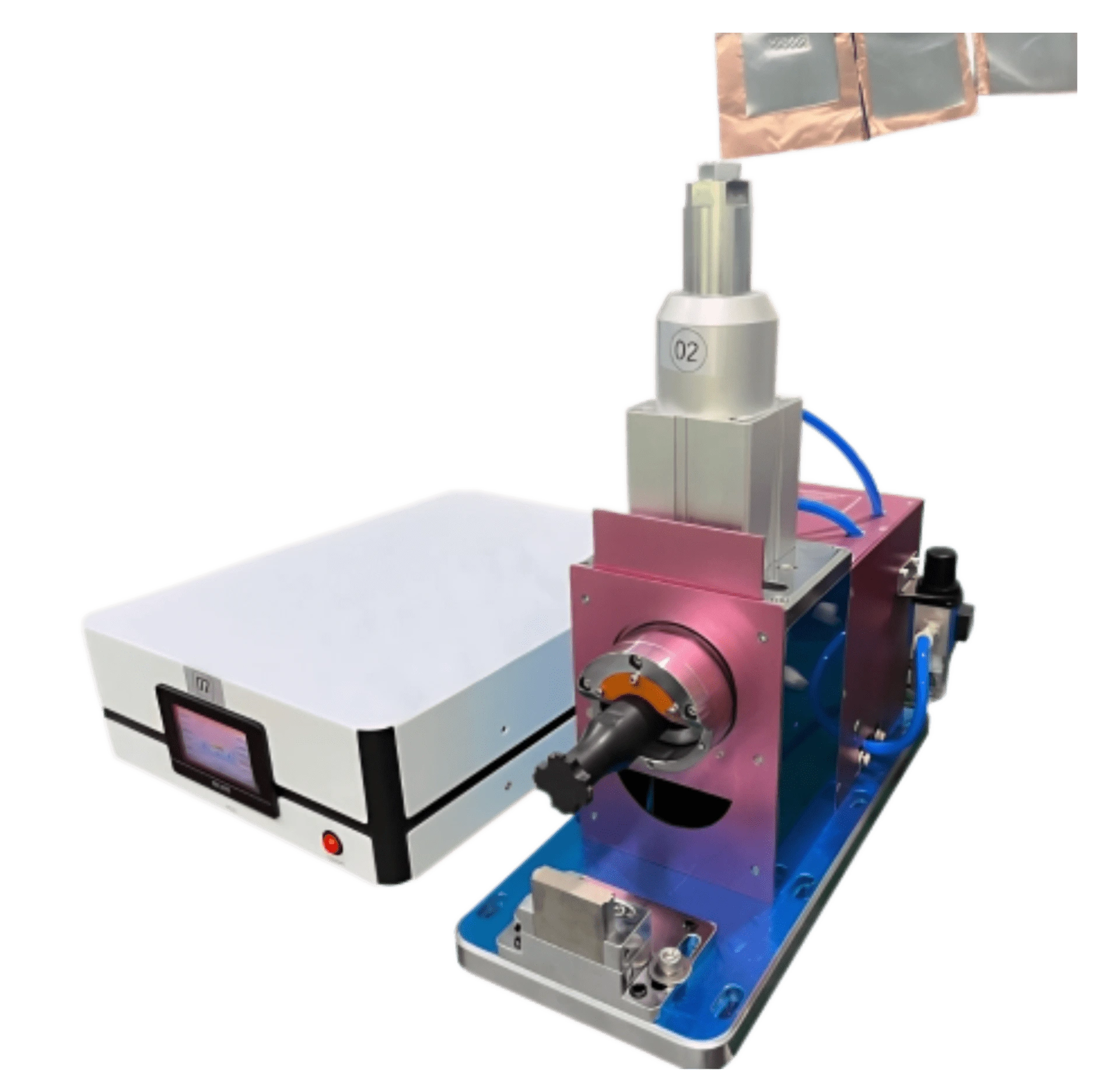

High Power Ultrasonic Metal Wire Terminal Welding Machine

High-Efficiency Ultrasonic Metal Spot Welding Power System

This system automatically monitors and adjusts to the transducer's frequency, offering dual control options: time-based and energy-based modes. Ultrasonic welding stands out for its minimal surface preparation requirements, removing the necessity to strip away oxide or electroplated coatings, all while maintaining exceptional efficiency and output quality.

During the welding process, the material stays solid without melting, preserving its original material properties and producing no environmental pollutants. Moreover, it facilitates flawless welding across a variety of metal pairings, including nickel with copper, copper with aluminum, and nickel with aluminum, to name a few.

This makes it the perfect choice for applications that demand dependable, clean, and adaptable metal joining solutions.

Product Detail

Application Scope

Welding wire harnesses from 1.5 mm² to 35 mm².

Used in automotive wire harness connections, wire end forming, wire inter-welding, and multi-wire interconnections.

Suitable for copper, aluminum, enameled wires, motor lead wires, etc.

Widely applied in automotive, electronics, motors, communication equipment, and instrumentation industries.

The digital ultrasonic generator is capable of real-time automatic frequency tracking, featuring adjustable amplitude ranging from 10% to 100% with a precision of 1%. Its protection mechanisms encompass overload safeguarding, input voltage protection, transducer voltage protection, and mold protection, ensuring top-notch performance tailored to your welding requirements.

Product parameters

| Parameter | Specification |

| Model | KM-JHN2050 |

| Air Pressure | 0.05 – 0.6 MPa |

| Operating Frequency | 20 kHz |

| Welding Range | 0.5 – 70 mm² |

| Terminal Thickness | ≤ 3 mm |

| Overall Dimensions | 650 × 350 × 780 mm |

| Frame Weight | Approximately 142 KG |

| Power Supply | 220 V |

| Applicable Materials | Copper wires, aluminum wires, copper-aluminum terminals |

| Motor Power | Customized |

| Power Options | 2000 W, 4200 W, 5600 W, 8000 W |

| Control Method | Single-chip |

| Maximum Output Power | 5000 W |

| Welding Time Range | 0.5S – 2S |

| Welding Area Range | Within 15 square mm (for spot welding context, but overall welding range is 0.5-70 mm²) |

| Operating Humidity | 0-40°C (likely meant temperature, but specified as humidity here; assuming temperature intended, corrected below in features if needed) |

| Working Pressure | 0.2 – 0.8 MPa |

| Ambient Temperature | 20-70°C |

| Chassis Dimensions | 58 × 18 × 46 cm |

| Bracket Dimensions | 46 × 15 × 14 cm |

| Features | Description |

| Multiple Welding Modes | Offers various welding modes to suit different requirements. |

| Compact Structure | Integrated design with a compact structure, lightweight, attractive appearance, and easy mobility. |

| User-Friendly Interface | Based on Windows 7 system with password protection and parameter program storage. |

| Barcode/QR Code Scanning | Enables product identification and tracking. |

| Process Data Storage | Supports product traceability by storing detailed process data. |

| Sequential Control | Allows precise control over welding sequences and individual operations. |

| Network Control | Supports remote control and real-time data monitoring. |

| Versatile Configurations | Offers multiple desktop setups for different production needs. |

| Production Line Integration | Designed for seamless integration into existing production lines. |

| PLC Frequency Tracking | Uses PLC phase-locked frequency automatic tracking technology for optimal welding results. |

| Cost-Effective | Achieves connections at minimal cost with excellent conductivity and low resistance. |

| Environmentally Friendly | No flux, gas, or solder required; short welding time. |

Download