Economy Model Ultrasonic Wire Harness Welding Machine

● Model KM-HMS-X00, welding area range: 0.35-10mm² according to the wire cross section;

● Gauge Wire Range: 7 AWG-21 AWG / 9 SWG -22 SWG

● Pneumatic motion control, competitive price for launching to market quickly

● Compact design

● Function for preventing missing soldering

● Suitable for soldering small-section area pure aluminum & copper wires.

Product Detail

Product description

The KM-HMS-X00 ultrasonic wire harness welder is a compact and efficient solution for most of your wire welding requirement. With its advanced features and user-friendly design, this machine is designed to satisfy most of your wire harness demand. The welded wires after welding is squeezed into square shape.

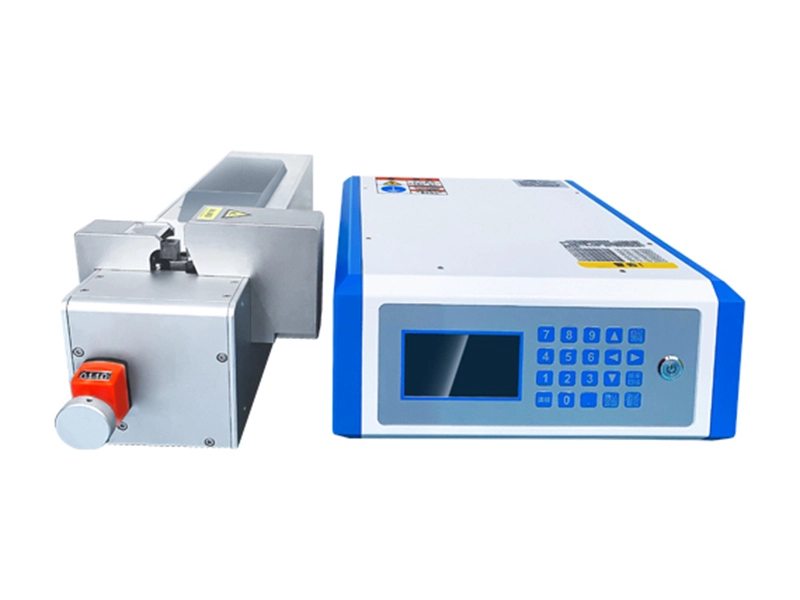

This machine consists of three main parts: ultrasonic generator, welding stack and start pedal. In the welding stack, the fixtures hold the wires in place,driven by necessary air pressure. The fixtures are composed of left and right sliders, easy for adjusting the welding width. Ultrasonic converter, booster and welding sonotrode are connected and placed in the housing of the stack.

The KM-HMS-X00 ultrasonic metal wire harness welding machine is ideal for various applications requiring reliable and precise wire welding. It finds extensive use in industries such as electronics, automotive, aerospace, and more. Whether you need to weld aluminum and/or copper wires, nickle wires, silver wires (all non-ferrous metals), this machine delivers exceptional results, ensuring strong and durable connections. Attention: enameled copper wires or tin-coated wires are not weldable by ultrasonic welders.

♦ ULTRASONIC GENERATOR

♦ 4.3-inch Color Screen + Key Press

The KM-HMS-X00 series ultrasonic wire harness welder is equipped with a key press panel on the ultrasonic generator with high-definition LED display, which can realize intuitive data, and real-time monitoring, thus having effectively guaranteed welding result. The function for preventing false weld is available in the design, which provides peace of mind for the user.

Structure of the welding stack

♦ COMPACT STRUCTURE

♦ Integrated Motion Control System

Equipped with pneumatic motion control, this machine is easy to operate, ensuring hassle-free wire welding. The welding range is 0.35-10mm² in terms of wires bundle section area, so it can be used for most of wire harness tasks.

Product parameters

|

Model |

KM-JHN2020 |

|

Freq. |

20kHz |

|

Max.Output Power |

2000W |

|

Weld mode |

Time |

|

Welding scope |

0.35-10mm² based on cross section area |

|

Single wire in OD |

≤0.3mm |

|

Power source voltage |

110/220VAC,50/60Hz |

|

Display screen size |

4.3-inch |

|

Motion control |

pneumatic |

|

Air source |

>0.5Mpa, filtered dry air |

|

Productivity |

0.5s/pcs, based on the wire condition |

|

Weight |

38KG NET |

|

Dimension(mm*mm*mm) |

Weld stack: 573*220*190 |