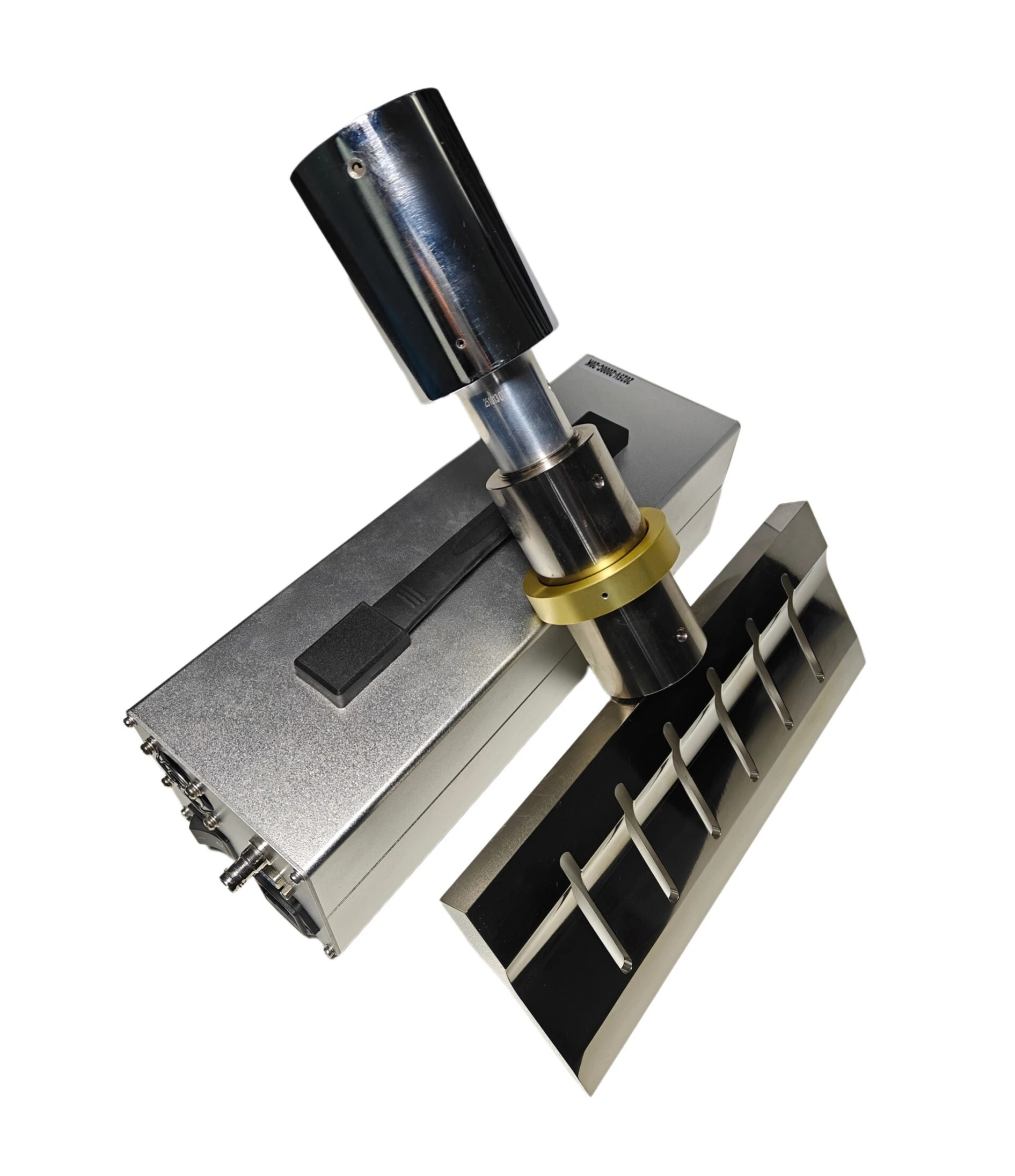

Ultrasonic Food Cutting Components Advanced Type KM-2000C

- User-Configurable Transducer Settings:Directly configure initial frequency and bandwidth parameters aligned with transducer specifications, enabling precise operational tuning.

- Dynamic Soft-Start & Amplitude Control:Integrated adjustable settings for soft-start duration, amplitude modulation, and operational timing within safe power thresholds, ensuring optimized performance and equipment longevity.

- On-Demand Scanning Activation:User-selectable scanning functionality at system startup, allowing flexible operation modes tailored to process requirements.

- Multi-Layer Electrical Protection System:Robust dual-channel safeguards (software/hardware) for voltage regulation, current limiting, and frequency stability, ensuring reliable operation under varying conditions.

- Remote Parameter Optimization via Host Interface:Facilitates real-time parameter adjustments through secure upper-computer communication protocols, enabling centralized control and diagnostic oversight without physical intervention.

Product Detail

Product description

Digital Ultrasonic Generator

The digital ultrasonic generator is capable of real-time automatic frequency tracking, featuring adjustable amplitude ranging from 10% to 100% with a precision of 1%. Its protection mechanisms encompass overload safeguarding, input voltage protection, transducer voltage protection, and mold protection, ensuring top-notch performance tailored to your welding requirements.

Ultrasonic Cutting Blade

Titanium Alloy Ultrasonic Cutting Blades, engineered through Finite Element Analysis (FEA), are crafted from premium titanium alloy to deliver superior efficiency and precision in food processing. These advanced blades generate an ultra-low-friction surface during operation, effectively preventing food adhesion and minimizing deformation, thus ensuring pristine cuts and optimized performance.

Product parameters

| Model | KM-2000C |

| Frequency | 20KHz |

| Power | 1000W |

| Material of Blade | Food industry approved Titanium |

| Cutting Width | 305mm |

| Cutting Height | 70mm |

| Input AC | 220V, 50Hz |

| Generator | Digital, Auto-tuning |

| Generator Weight | 3.2kg |

| Dimension of Generator | 395mm*120mm*110mm |

| (L*W*H) |

Product display