Unlocking The Power Of Ultrasonic Generators: A Comprehensive Guide

Are you curious about how ultrasonic generators can revolutionize various industries and processes? In this comprehensive guide, we will delve into the ins and outs of ultrasonic technology and how these powerful generators can unlock a world of possibilities. Join us as we explore the potential of ultrasonic generators and how they can enhance efficiency, precision, and innovation in numerous applications. Whether you are a novice or an expert in the field, this guide will provide valuable insight into harnessing the power of ultrasonic technology. Let's unlock the extraordinary potential of ultrasonic generators together.

- Understanding Ultrasonic Technology

Ultrasonic technology has revolutionized various industries, from medical to cleaning to manufacturing. At the heart of this technology lies ultrasonic generators, which are crucial for producing high-frequency sound waves that are beyond the range of human hearing. In this comprehensive guide, we will delve into the intricacies of ultrasonic generators and how they work to unlock the power of ultrasonic technology.

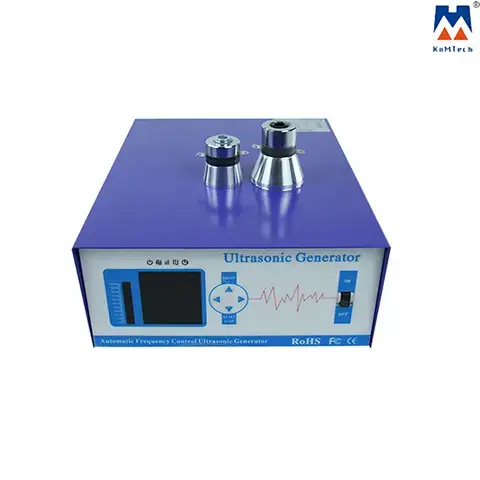

Ultrasonic generators are essential components of ultrasonic systems, as they are responsible for converting electrical energy into high-frequency mechanical vibrations. These vibrations are then transmitted to a transducer, which converts them into ultrasonic waves that can be used for a variety of applications. The key to the success of ultrasonic generators lies in their ability to produce consistent and reliable vibrations, which are essential for achieving optimal results in ultrasonic cleaning, welding, cutting, and other processes.

There are several types of ultrasonic generators available on the market, ranging from analog to digital to programmable models. Analog generators are simple and easy to use, but they lack the precision and control offered by digital and programmable generators. Digital generators, on the other hand, offer greater flexibility and precision, allowing users to adjust parameters such as frequency, power, and time to suit specific applications. Programmable generators take this a step further by allowing users to create custom programs for different applications, making them ideal for complex and specialized tasks.

When selecting an ultrasonic generator, it is important to consider factors such as frequency range, power output, and control options. The frequency range of the generator should match the requirements of the specific application, as different frequencies are more effective for different tasks. The power output of the generator should also be sufficient to ensure that the transducer can produce the desired level of ultrasonic energy. Finally, the control options of the generator should be easy to use and provide the necessary flexibility for adjusting parameters as needed.

In addition to selecting the right generator, it is also important to consider the overall setup of the ultrasonic system. This includes the type of transducer, the material being processed, and the cleaning or processing solution being used. By optimizing all these factors, users can maximize the efficiency and effectiveness of their ultrasonic system.

In conclusion, ultrasonic generators play a vital role in unlocking the power of ultrasonic technology. By understanding how these generators work and selecting the right one for the task at hand, users can harness the full potential of ultrasonic technology for a wide range of applications. Whether it is cleaning delicate medical instruments or welding precision components, ultrasonic generators are the key to achieving superior results. So, take the time to delve into the world of ultrasonic technology and discover the endless possibilities that await with the power of ultrasonic generators.

- Types of Ultrasonic Generators

Ultrasonic generators are essential tools in a wide range of industries, from manufacturing to medical imaging. These generators produce high-frequency sound waves that are beyond the range of human hearing, typically above 20 kHz. They are utilized for various applications, including cutting, welding, cleaning, and sterilizing. Types of ultrasonic generators vary depending on their design, power output, and frequency range. In this comprehensive guide, we will delve deeper into the different types of ultrasonic generators available in the market.

1. Analog Ultrasonic Generators:

Analog ultrasonic generators are the most basic type of generators and operate at a fixed frequency. They are commonly used for simple applications that do not require precise control over the frequency of the sound waves. Analog generators are easy to operate and are cost-effective, making them suitable for industries with limited budgets.

2. Digital Ultrasonic Generators:

Digital ultrasonic generators offer more advanced features compared to analog generators. They allow users to control the frequency, amplitude, and duration of the sound waves with greater precision. This level of control is essential for applications that require high accuracy and repeatability, such as ultrasonic welding and cutting. Digital generators are also programmable, allowing for automated processes and increased efficiency.

3. Sweep Ultrasonic Generators:

Sweep ultrasonic generators are capable of varying the frequency of the sound waves over a specific range. This feature is useful for applications that require a broader spectrum of frequencies to achieve optimal results. Sweep generators are commonly used in ultrasonic cleaning equipment, where different frequencies are needed to remove debris and contaminants from surfaces effectively.

4. Dual-Frequency Ultrasonic Generators:

Dual-frequency ultrasonic generators are designed to operate at two distinct frequencies simultaneously. This unique feature allows for more versatility in applications that require multiple frequencies for different tasks. For example, dual-frequency generators can be used in medical imaging equipment to produce higher quality images by combining two frequencies to enhance the resolution and clarity of the images.

5. Multi-Channel Ultrasonic Generators:

Multi-channel ultrasonic generators are capable of driving multiple transducers simultaneously, providing a more efficient and powerful output. These generators are ideal for high-intensity applications that require a higher level of energy. Multi-channel generators are commonly used in industrial processes such as ultrasonic welding of large components or high-speed cleaning of industrial equipment.

In conclusion, ultrasonic generators come in various types to suit different applications and industries. Choosing the right type of generator is crucial for achieving optimal results and maximizing the potential of ultrasonic technology. Whether you need precise control over the frequency, variable frequency range, or high-intensity output, there is a generator available to meet your specific requirements. By understanding the types of ultrasonic generators and their capabilities, you can unlock the power of ultrasonic technology and harness its full potential in your operations.

- Applications of Ultrasonic Generators

Ultrasonic generators have revolutionized various industries with their wide range of applications. From cleaning to welding, these powerful devices have proven to be essential tools in modern technology. In this comprehensive guide, we will explore the various applications of ultrasonic generators and how they are unlocking new possibilities in different fields.

One of the most common uses of ultrasonic generators is in the field of cleaning. Ultrasonic cleaning involves the use of high-frequency sound waves to agitate a cleaning solution, effectively removing dirt, grime, and contaminants from surfaces. This method is often used in industries such as manufacturing, healthcare, and electronics, where precision cleaning is crucial. Ultrasonic generators are able to deep clean delicate items such as jewelry, medical instruments, and circuit boards without causing damage.

Another important application of ultrasonic generators is in the field of welding. Ultrasonic welding is a process that uses high-frequency vibrations to join two materials together. This method is often used in industries such as automotive, aerospace, and packaging, where strong and reliable bonds are required. Ultrasonic generators are able to create solid welds without the need for heat or additional materials, making them an efficient and cost-effective welding solution.

In the medical field, ultrasonic generators are used in various applications such as medical imaging, surgery, and therapy. Ultrasonic imaging, also known as ultrasound, uses sound waves to create images of internal organs and tissues. This non-invasive imaging technique is widely used for diagnostics and monitoring during medical procedures. Ultrasonic generators are also used in surgical procedures such as liposuction and cataract removal, where precision and accuracy are essential.

Furthermore, ultrasonic generators have found applications in the food industry for processes such as cutting, mixing, and emulsifying. Ultrasonic cutting uses high-frequency vibrations to slice through food products with precision and minimal waste. Ultrasonic mixing is used to blend ingredients together evenly, while ultrasonic emulsifying is used to create stable emulsions with a fine particle size. These applications have improved efficiency and quality control in the food manufacturing process.

In conclusion, the applications of ultrasonic generators are vast and diverse, ranging from cleaning and welding to medical imaging and food processing. These powerful devices have revolutionized various industries by unlocking new possibilities and improving efficiency. As technology continues to advance, ultrasonic generators will continue to play a crucial role in shaping the future of innovation and progress.

- Factors to Consider When Choosing an Ultrasonic Generator

Ultrasonic generators are powerful tools that are widely used in various industries such as manufacturing, cleaning, and medical. They work by converting electrical energy into high-frequency vibrations, which are then used to power ultrasonic transducers. These transducers generate ultrasonic waves that can be used for a wide range of applications, including cleaning, welding, cutting, and more.

When choosing an ultrasonic generator, there are several factors that need to be considered to ensure that you get the best performance and results. In this comprehensive guide, we will discuss some of the key factors that you should keep in mind when selecting an ultrasonic generator.

The first factor to consider when choosing an ultrasonic generator is the frequency range. Different applications require different frequencies, so it is important to choose a generator that can provide the right frequency for your specific needs. Generators typically operate at frequencies ranging from 20 kHz to 100 kHz, so make sure to choose one that is compatible with your application.

Another important factor to consider is the power output of the generator. The power output will determine how effectively the generator can generate ultrasonic waves, so it is important to choose a generator that has sufficient power for your needs. Higher power generators are generally more expensive, but they can provide better performance and results.

It is also important to consider the size and portability of the generator. Some applications require a portable generator that can be easily moved around, while others may require a larger, stationary generator. Consider the size and weight of the generator to ensure that it is suitable for your specific application.

When choosing an ultrasonic generator, it is essential to consider the type of control system it has. Some generators have simple on/off switches, while others have more advanced control systems that allow for precise adjustments of frequency, power output, and other settings. Choose a generator with a control system that is easy to use and allows for fine-tuning of the ultrasonic settings.

It is also important to consider the overall quality and reliability of the generator. Look for generators that are made from high-quality materials and have a reputation for reliability. It is worth investing in a high-quality generator that will provide consistent performance over time.

In conclusion, when choosing an ultrasonic generator, it is important to consider factors such as frequency range, power output, size, control system, and overall quality. By carefully considering these factors, you can ensure that you choose the right generator for your specific application and unlock the full power of ultrasonic technology.

- Tips for Maximizing the Efficiency of Ultrasonic Generators

Ultrasonic generators are a powerful tool in various industries, from manufacturing to medical applications, thanks to their ability to produce high-frequency sound waves that can clean, cut, weld, and even heal. However, to truly unlock the full potential of ultrasonic generators, it is essential to understand how to maximize their efficiency. In this comprehensive guide, we will provide you with valuable tips and tricks to help you make the most of your ultrasonic generator.

One of the key factors to consider when using an ultrasonic generator is the frequency at which it operates. Different applications require different frequencies, so it is important to adjust the settings of the generator accordingly. Generally, higher frequencies are used for delicate tasks such as cleaning precision instruments, while lower frequencies are better suited for cutting or welding thicker materials. By understanding the specific requirements of your application, you can ensure that you are using the optimal frequency for maximum efficiency.

Another important aspect of maximizing the efficiency of an ultrasonic generator is ensuring that it is properly maintained. Regular maintenance, such as cleaning the transducers and checking for any loose connections, can help prevent malfunctions and prolong the lifespan of the generator. Additionally, replacing worn-out parts and keeping the generator well-lubricated can also contribute to its overall efficiency.

Furthermore, proper setup and calibration of the ultrasonic generator are crucial for achieving optimal performance. This includes positioning the transducers at the correct distance and angle, as well as ensuring that the power settings are adjusted according to the requirements of the task at hand. By taking the time to properly set up and calibrate your ultrasonic generator, you can avoid wasting energy and ensure that it operates at its full potential.

In addition to these practical tips, there are also some advanced techniques that can help you maximize the efficiency of your ultrasonic generator. For example, using pulse width modulation (PWM) to control the power output of the generator can help improve its overall performance and efficiency. By varying the width of the pulses, you can adjust the power level of the generator with greater precision, allowing you to achieve the desired results more effectively.

Overall, by following these tips and techniques, you can unlock the full power of your ultrasonic generator and take your applications to the next level. Whether you are using it for cleaning, cutting, welding, or any other task, maximizing the efficiency of your ultrasonic generator can help you save time, energy, and resources while achieving superior results. So, don't wait any longer – start implementing these strategies today and see the difference for yourself.

Conclusion

In conclusion, after exploring the vast potential of ultrasonic generators in this comprehensive guide, it is clear that these devices hold immense power and versatility for various industrial applications. With 9 years of experience in the industry, our company is well-equipped to help unlock the full potential of ultrasonic generators for our clients. By harnessing the power of ultrasonic technology, businesses can achieve unprecedented levels of efficiency, precision, and cost-effectiveness. It is truly an exciting time to be at the forefront of innovation in this field, and we look forward to continuing to push the boundaries of what is possible with ultrasonic generators.