Overview Of Ultrasonic Generators In Modern Manufacturing

Welcome to our comprehensive overview of ultrasonic generators in modern manufacturing. In today's fast-paced and highly technological world, ultrasonic generators have revolutionized the manufacturing industry, offering a wide range of benefits from increased efficiency to improved product quality. Whether you are new to the concept of ultrasonic generators or are looking to stay up-to-date with the latest advancements in manufacturing technology, this article is your go-to resource for understanding the role of ultrasonic generators in modern manufacturing processes. Join us as we delve into the intricacies of ultrasonic generators and how they are shaping the future of manufacturing.

Overview of Ultrasonic Generators in Modern Manufacturing

Ultrasonic generators play a crucial role in modern manufacturing processes, providing a high-frequency ultrasonic vibration that is used for a variety of applications such as cutting, welding, cleaning, and soldering. In this article, we will discuss the importance of ultrasonic generators in modern manufacturing and how they have revolutionized the industry.

1. The Advantages of Ultrasonic Generators

Ultrasonic generators offer several advantages in modern manufacturing processes. One of the most significant benefits is their ability to provide a highly precise and localized energy input, making them ideal for intricate and delicate tasks. Additionally, ultrasonic generators are capable of producing a clean and controlled energy source, resulting in minimal damage to surrounding materials. This makes them suitable for a wide range of materials, including metals, ceramics, plastics, and composites. Furthermore, ultrasonic generators are energy-efficient and cost-effective, providing a sustainable solution for modern manufacturing processes.

2. Applications of Ultrasonic Generators

Ultrasonic generators are used in various manufacturing applications, including welding, cutting, cleaning, and soldering. In welding, ultrasonic generators are employed to create a strong and reliable bond between two materials by generating high-frequency vibrations that melt and fuse the materials together. Similarly, in cutting processes, ultrasonic generators provide a precise and efficient method for cutting materials without generating heat, resulting in a clean and accurate cut. In addition, ultrasonic generators are commonly used in cleaning applications, where they produce high-frequency vibrations to remove contaminants from surfaces without causing damage. Furthermore, ultrasonic generators are utilized in soldering processes to create a secure and durable joint between electronic components.

3. The Role of Ultrasonic Generators in Advanced Manufacturing Technologies

Ultrasonic generators have become an integral part of advanced manufacturing technologies, playing a crucial role in the development of innovative and high-precision manufacturing processes. One notable example is additive manufacturing, where ultrasonic generators are utilized to enhance the efficiency and accuracy of 3D printing processes. By integrating ultrasonic vibrations into the 3D printing process, manufacturers can achieve higher levels of detail and resolution, resulting in the production of complex and intricate components. Additionally, ultrasonic generators are used in the development of advanced machining techniques, such as ultrasonic-assisted machining, which combines conventional machining processes with ultrasonic vibrations to improve cutting efficiency and reduce tool wear.

4. The Future of Ultrasonic Generators in Manufacturing

The future of ultrasonic generators in manufacturing looks promising, with an increasing focus on their role in enhancing sustainability and reducing environmental impact. As manufacturers strive to adopt more eco-friendly practices, ultrasonic generators provide a viable solution by offering energy-efficient and precise manufacturing processes. Furthermore, the integration of ultrasonic generators with advanced robotics and automation technologies is expected to revolutionize the manufacturing industry, enabling the production of highly complex and customized products with unparalleled accuracy and efficiency.

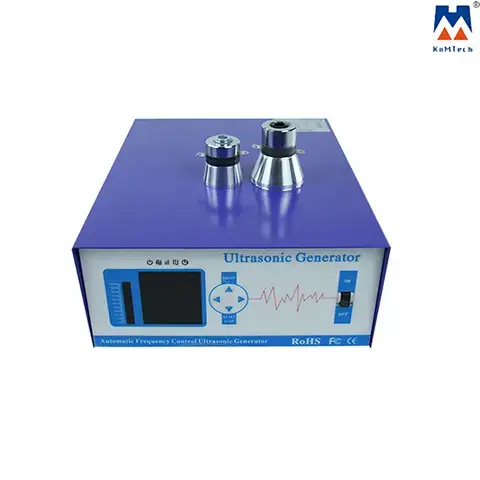

5. KnMTech: The Leading Provider of Ultrasonic Generators

As a pioneering company in the field of ultrasonic technology, KnMTech is dedicated to providing cutting-edge ultrasonic generators for modern manufacturing applications. With a strong commitment to innovation and quality, KnMTech offers a wide range of ultrasonic generators that are designed to meet the diverse needs of the manufacturing industry. From precision welding and cutting to advanced cleaning and soldering processes, KnMTech's ultrasonic generators are trusted by manufacturers worldwide for their reliability, efficiency, and performance. With a focus on sustainability and technological advancement, KnMTech is shaping the future of manufacturing with its state-of-the-art ultrasonic generators.

Conclusion

In conclusion, ultrasonic generators have revolutionized modern manufacturing with their ability to efficiently and effectively carry out a wide range of processes such as cleaning, cutting, welding, and more. As a company with 9 years of experience in the industry, we have witnessed firsthand the transformative impact of ultrasonic generators on production processes. Their versatility, precision, and eco-friendly nature make them a valuable asset for any manufacturing operation. With ongoing advancements in technology, we can expect to see even more innovative applications of ultrasonic generators in the future, further enhancing the efficiency and sustainability of modern manufacturing.