Ultrasonic Wire Welder: Revolutionizing Wire Bonding Processes

Welcome to the future of wire bonding processes! The Ultrasonic Wire Welder is changing the game with its revolutionary technology, providing more efficient and reliable wire bonding solutions. In this article, we will delve into how this innovative tool is transforming the industry and its potential impact on various applications. Whether you're a professional in the field or just curious about the latest advancements in welding technology, this is a must-read to stay ahead of the curve. Join us as we explore the exciting world of ultrasonic wire welding and its potential to revolutionize the wire bonding process.

Ultrasonic Wire Welder: Revolutionizing Wire Bonding Processes

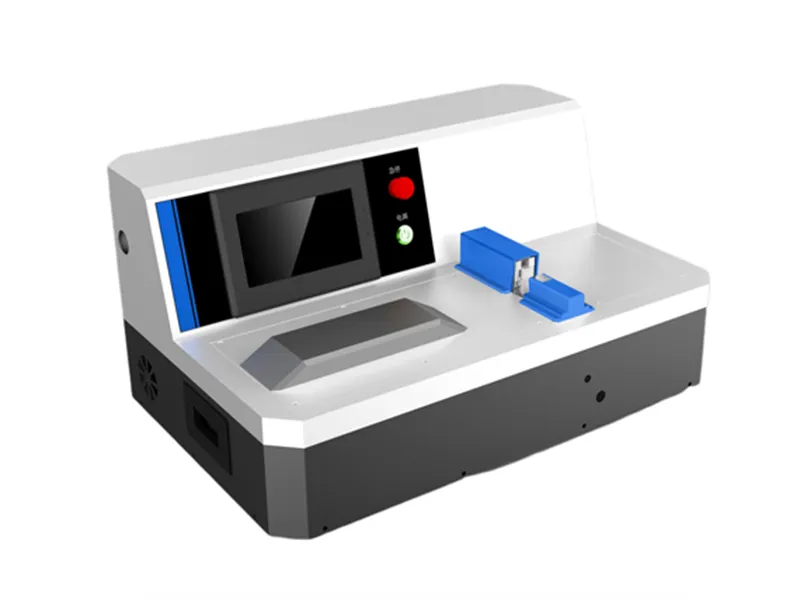

In the world of manufacturing and electronics, wire bonding is a critical process used to connect wires to semiconductor devices, creating a reliable and durable connection. Traditionally, wire bonding has been done using thermal compression or ultrasonic bonding techniques. However, recent advancements in technology have led to the development of a new innovation – the Ultrasonic Wire Welder – which is revolutionizing wire bonding processes across various industries. This cutting-edge tool offers unparalleled performance, precision, and efficiency, making it an indispensable asset for manufacturers and electronics engineers.

Introducing KnMTech: The Innovators Behind the Ultrasonic Wire Welder

As the demand for smaller, faster, and more reliable electronic devices continues to grow, the need for advanced wire bonding solutions has never been more crucial. This is where KnMTech, also known as K&M Technologies Ltd., has become a leading force in the industry. With a commitment to innovation and excellence, KnMTech has developed the Ultrasonic Wire Welder to address the challenges and limitations of traditional wire bonding methods.

The Ultrasonic Wire Welder: A Game-Changing Technology

The Ultrasonic Wire Welder from KnMTech stands out as a game-changing technology due to its unique capabilities and performance benefits. Unlike traditional wire bonding methods that rely on heat and pressure to create a bond, the Ultrasonic Wire Welder utilizes ultrasonic vibrations to create a solid and reliable connection between the wire and the semiconductor device. This non-destructive bonding process reduces the risk of damage to sensitive components and ensures a high level of precision and consistency in wire bonding applications.

Enhanced Efficiency and Productivity

One of the key advantages of the Ultrasonic Wire Welder is its ability to significantly enhance efficiency and productivity in wire bonding processes. With its advanced automation features and rapid bonding capabilities, the Ultrasonic Wire Welder enables manufacturers to achieve higher throughput and reduced cycle times without compromising the quality of the bonds. This not only leads to cost savings but also allows for quicker turnaround times and increased production capacity.

Precision and Reliability in Wire Bonding

Precision and reliability are paramount in wire bonding applications, especially in the manufacturing of complex electronic devices. The Ultrasonic Wire Welder excels in delivering consistent and reliable bonding results, thanks to its highly controlled ultrasonic energy and force. This level of precision ensures that the wire bonds meet stringent quality standards and exhibit strong mechanical and electrical properties, essential for the performance and longevity of the final electronic products.

Versatility and Adaptability Across Industries

From automotive and aerospace to telecommunications and medical electronics, the Ultrasonic Wire Welder from KnMTech offers versatility and adaptability across a wide range of industries. This flexibility allows manufacturers and electronics engineers to utilize this cutting-edge technology for various wire bonding applications, including fine-pitch bonding, ball bonding, and wedge bonding, to name a few. The Ultrasonic Wire Welder's ability to accommodate different wire materials and bond configurations makes it a versatile solution for diverse manufacturing needs.

In conclusion, the Ultrasonic Wire Welder from KnMTech represents a significant advancement in wire bonding technology. Its precision, reliability, efficiency, and versatility make it a game-changer for manufacturers and electronics engineers seeking to elevate their wire bonding processes. As the demand for high-performance electronic devices continues to soar, the Ultrasonic Wire Welder is poised to play a pivotal role in shaping the future of wire bonding across various industries.

Conclusion

In conclusion, the ultrasonic wire welder has indeed revolutionized the wire bonding processes in the industry. With our 9 years of experience, we have seen firsthand the impact that this innovative technology has had on increasing efficiency, precision, and overall quality of wire bonding. As we continue to embrace new advancements and technologies in the field, we are excited to see how the ultrasonic wire welder will continue to push the boundaries of wire bonding processes, ultimately leading to even greater advancements in the industry. We look forward to being at the forefront of these exciting developments and are dedicated to providing our customers with the highest quality wire bonding solutions.