Revolutionizing Welding: The Power Of The Ultrasonic Wire Welder

Are you ready to discover the game-changing technology revolutionizing the world of welding? Introducing the ultrasonic wire welder, a powerful tool that is transforming the way we connect and fabricate metal materials. In this article, we will explore the capabilities and benefits of this cutting-edge technology and how it is reshaping the future of welding. Join us as we delve into the world of ultrasonic wire welding and uncover the endless possibilities it offers for manufacturers and fabricators.

- Introduction to Ultrasonic Wire Welding

to Ultrasonic Wire Welding

In the world of manufacturing, welding plays a crucial role in joining metals together to create a wide variety of products. Historically, welding has primarily been done using techniques such as arc welding, resistance welding, and laser welding. However, a relatively new welding technology has been revolutionizing the industry - the ultrasonic wire welder.

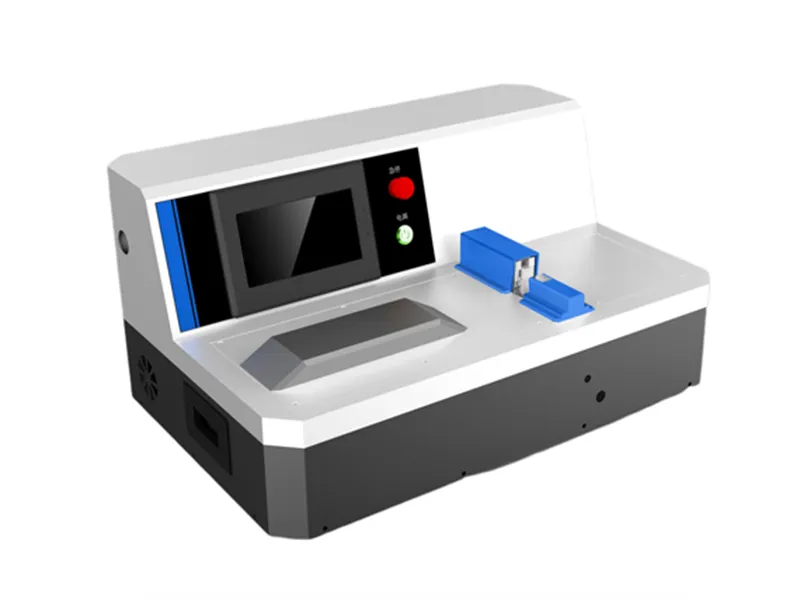

The ultrasonic wire welder is a cutting-edge welding machine that uses ultrasonic vibrations to weld two pieces of wire together. This technology offers a number of significant advantages over traditional welding methods. One of the key benefits of ultrasonic wire welding is its ability to produce high-quality welds with minimal heat input. This is particularly important when working with sensitive materials or components that can be damaged by excessive heat.

Another advantage of ultrasonic wire welding is its ability to weld dissimilar metals together. Traditional welding methods often struggle to join different types of metals, but the ultrasonic wire welder is capable of creating strong, reliable welds between metals with different properties. This opens up a world of possibilities for manufacturers, enabling them to create new and innovative products that were previously impossible to fabricate.

In addition to its versatility, the ultrasonic wire welder is also incredibly efficient. The machine is able to perform fast, precise welds with minimal operator intervention, reducing production time and costs. This makes it an attractive option for manufacturers looking to streamline their welding processes and increase overall productivity.

Furthermore, the ultrasonic wire welder is also environmentally friendly. Unlike traditional welding methods that produce harmful fumes and emissions, ultrasonic wire welding is a clean, energy-efficient process that generates very little waste. This not only benefits the environment but also creates a safer and healthier work environment for operators.

Overall, the ultrasonic wire welder is a game-changer in the world of welding. Its advanced technology, versatility, efficiency, and environmental benefits make it a compelling choice for manufacturers looking to take their welding processes to the next level. As the industry continues to evolve, it is clear that the ultrasonic wire welder will play a key role in shaping the future of welding technology.

- Advantages of Ultrasonic Wire Welding

Ultrasonic wire welding is a cutting-edge technology that is revolutionizing the welding industry. This innovative method offers a wide range of advantages that make it superior to traditional welding techniques. From increased efficiency to improved quality, the ultrasonic wire welder is quickly becoming the go-to choice for manufacturers looking to optimize their welding processes.

One of the key advantages of ultrasonic wire welding is its ability to produce strong, reliable welds with minimal heat input. Unlike traditional welding methods that rely on high temperatures to melt and fuse materials together, ultrasonic wire welding uses high-frequency vibrations to create friction and bond the materials. This results in a more precise and controlled welding process that produces durable welds without distorting or damaging the materials.

In addition to its precision and control, ultrasonic wire welding offers significant time and cost savings. The high-speed vibration process allows for faster welding speeds, reducing overall production time. This increased efficiency translates to lower labor costs and higher output for manufacturers. Furthermore, the minimal heat input of ultrasonic wire welding means that less power is required, resulting in lower energy consumption and reduced operating costs.

Another advantage of ultrasonic wire welding is its versatility. This technology can be used to weld a wide range of materials, including metals, plastics, and composites. Whether joining dissimilar materials or creating intricate welds in hard-to-reach areas, the ultrasonic wire welder offers unmatched flexibility for a variety of welding applications. This versatility makes it an ideal choice for industries such as automotive, aerospace, and electronics, where precision and strength are paramount.

The ultrasonic wire welder also provides superior weld quality compared to traditional welding methods. The controlled vibration process ensures that the weld is free from defects such as porosity, cracking, or incomplete fusion. This results in stronger, more reliable welds that meet or exceed industry standards. Additionally, the non-contact nature of ultrasonic wire welding minimizes the risk of contamination and ensures a clean, high-quality finish.

Overall, the advantages of ultrasonic wire welding are clear. From increased efficiency and cost savings to superior weld quality and versatility, this innovative technology is transforming the welding industry. Manufacturers looking to optimize their welding processes and improve their overall productivity should consider incorporating the ultrasonic wire welder into their operations. With its advancements in technology and numerous benefits, the ultrasonic wire welder is truly a game-changer in the world of welding.

- Applications of Ultrasonic Wire Welding

Ultrasonic wire welding is revolutionizing the welding industry with its advanced applications and capabilities. This innovative technology utilizes high-frequency vibrations to bond wires together without the need for heat or soldering. The ultrasonic wire welder is a powerful tool that offers numerous advantages over traditional welding methods.

One of the key applications of the ultrasonic wire welder is in the automotive industry. The ability to quickly and securely bond wires together makes it an ideal solution for creating strong and reliable electrical connections in vehicles. This technology has been widely adopted by automotive manufacturers to improve the efficiency and durability of their products.

Another important application of the ultrasonic wire welder is in the electronics industry. With the increasing demand for smaller and more complex electronic devices, the need for precise and reliable wire bonding solutions has never been greater. The ultrasonic wire welder offers a cost-effective and efficient way to bond wires together, creating tight connections that are essential for the proper functioning of electronic components.

In addition to automotive and electronics applications, the ultrasonic wire welder is also being used in other industries such as aerospace, medical, and telecommunications. Its versatility and precision make it a valuable tool for a wide range of applications, where strong and reliable wire connections are required.

One of the key benefits of using an ultrasonic wire welder is its ability to produce high-quality welds without the use of heat. This minimizes the risk of damaging sensitive components and materials, making it an ideal solution for bonding wires in delicate electronic devices or medical equipment. The precision and control offered by the ultrasonic wire welder also make it a popular choice for welding thin wires or complex shapes.

Additionally, the ultrasonic wire welder is a cost-effective solution for manufacturers looking to streamline their production processes. The ability to quickly and accurately bond wires together reduces the need for manual labor and ensures consistent results every time. This can lead to increased productivity and lower operational costs for companies in a variety of industries.

Overall, the ultrasonic wire welder is a game-changing technology that is revolutionizing the welding industry. Its advanced applications and capabilities make it a valuable tool for a wide range of industries, offering precision, efficiency, and cost-effectiveness. As technology continues to evolve, the ultrasonic wire welder is sure to play an increasingly important role in modern manufacturing processes.

- Future Developments in Ultrasonic Wire Welding Technology

With the continuous advancement of technology in the welding industry, the ultrasonic wire welder has emerged as a game-changer in revolutionizing traditional welding techniques. This innovative technology utilizes ultrasonic vibrations to create efficient and high-quality welds, making it a preferred choice for various industries.

One of the key features of the ultrasonic wire welder is its ability to weld materials with precision and accuracy. The ultrasonic vibrations generated by the machine help to soften the materials being welded, creating a strong bond that is free from defects. This technology ensures that welds are consistent and reliable, leading to improved overall product quality.

In addition to its superior welding capabilities, the ultrasonic wire welder also offers a number of other advantages. For example, the technology is highly versatile and can be used to weld a wide range of materials, including metals, plastics, and composites. This makes it an ideal choice for industries that require diverse welding applications.

Furthermore, the ultrasonic wire welder is known for its efficiency and cost-effectiveness. Compared to traditional welding methods, this technology allows for faster welding speeds and reduced heat input, resulting in lower energy consumption and reduced production costs. This makes it an attractive option for businesses looking to increase their productivity while maintaining high standards of quality.

Looking towards the future, there are several exciting developments on the horizon for ultrasonic wire welding technology. Researchers and manufacturers are continually exploring ways to enhance the capabilities of the ultrasonic wire welder, with a focus on improving welding speed, accuracy, and reliability. This includes advancements in machine design, software integration, and material compatibility.

One potential area of development is the integration of robotics and automation with ultrasonic wire welding technology. By combining robotic systems with the precision and efficiency of ultrasonic welding, manufacturers can further enhance their production processes and streamline operations. This not only increases productivity but also reduces the risk of human error, leading to higher quality welds.

Another area of interest is the development of new materials and alloys that are compatible with ultrasonic wire welding technology. By expanding the range of materials that can be welded using this technology, manufacturers can open up new opportunities for innovation and product development. This could lead to the creation of stronger, lighter, and more durable products that meet the demands of modern industries.

In conclusion, the ultrasonic wire welder is set to have a significant impact on the future of welding technology. With its superior welding capabilities, versatility, efficiency, and potential for future developments, this technology is poised to revolutionize the way we think about welding. As researchers and manufacturers continue to explore new possibilities, we can expect to see even more innovative applications and advancements in ultrasonic wire welding technology in the years to come.

- Conclusion: The Impact of Ultrasonic Wire Welding on the Welding Industry

The ultrasonic wire welder has ushered in a new era for the welding industry, revolutionizing the way in which metals are joined together. This groundbreaking technology has had a profound impact on welding processes and has rapidly gained popularity among industry professionals. In this article, we will explore the key features and benefits of the ultrasonic wire welder, and discuss how it has transformed the welding industry.

One of the key advantages of the ultrasonic wire welder is its ability to produce strong and reliable welds with minimal heat input. Unlike traditional welding methods, which rely on high temperatures to melt the base metals, ultrasonic wire welding uses ultrasonic vibrations to create friction and bond the materials together. This results in a significantly lower heat-affected zone, reducing the risk of distortion and weakening of the materials. As a result, welds made with an ultrasonic wire welder are stronger and more durable, making them ideal for a wide range of applications.

In addition to its superior strength, the ultrasonic wire welder also offers increased precision and control over the welding process. The ultrasonic vibrations allow for precise control over the weld penetration depth and width, ensuring consistent and high-quality welds every time. This level of precision is particularly valuable in industries where accuracy is critical, such as aerospace and automotive manufacturing.

Furthermore, the ultrasonic wire welder is highly versatile and can be used to weld a wide variety of materials, including aluminum, stainless steel, and other exotic alloys. This flexibility makes it a valuable tool for a wide range of industries, from automotive and aerospace to electronics and medical device manufacturing. Additionally, the ultrasonic wire welder is well-suited for welding dissimilar materials, making it an ideal choice for joining materials with different thermal properties or melting points.

The impact of the ultrasonic wire welder on the welding industry has been profound, with many companies embracing this advanced technology to improve the quality and efficiency of their welding operations. By reducing heat input, increasing precision, and offering versatility in materials, the ultrasonic wire welder has set a new standard for welding excellence.

As the welding industry continues to evolve, the ultrasonic wire welder is sure to play an increasingly important role in shaping the future of welding technology. With its unmatched strength, precision, and versatility, the ultrasonic wire welder is poised to revolutionize the way metals are joined together, setting new standards for quality and efficiency in the welding industry.

Conclusion

In conclusion, the ultrasonic wire welder has truly revolutionized the welding industry with its power and precision. With 9 years of experience in the field, our company has witnessed firsthand the incredible impact this technology has had on our work. As we continue to harness the power of ultrasonic wire welding, we are excited to see the endless possibilities and advancements it will bring to the industry. The future of welding is bright, thanks to the innovation and efficiency of the ultrasonic wire welder.