Ultrasonic Fabric Cutter - Company - KnMTech

Product details of the ultrasonic fabric cutter

Quick Overview

With time going on, the advantages for ultrasonic fabric cutter are more obvious and attract more customers. All incoming materials are inspected to ensure they match the quality requirement. K&M Technologies Ltd.'s ultrasonic fabric cutter is widely used in various industries and fields. KnMTech is mainly engaged in ultrasonic fabric cutter business, which only provides the best quality.

Product Information

Our ultrasonic fabric cutter has the following differentiated advantages compared to similar products.

Product Detail

Product description

The advanced type ultrasonic food cutting system includes an ultrasonic generator, an ultrasonic converter, and a cutting blade. The generator is the digital type, you can set ultrasonic technical parameters on the panel, and it also supports RS485 communication, 20kHz, 30kHz, 40kHz available. The ultrasonic cutting blade is produced by effective FDA analysis, and crafted with titanium alloy. During food cutting, the ultrasonic cutting blade will create a nearly frictionless cutting surface, making the cutting of sticky, layered, and hard food easier. It is suitable for food such as cakes, bread, nuts, nougat, sandwiches, biscuits, dough, cheese, fresh honey, candies, and so on.

Knmtech have been in the ultrasonic cutting industry for over 15 years. our ultrasonic cutting components are widely used in various food factories all over the world with the impression of high quality and reliability.

♦ ULTRASONIC GENERATOR

Digital Ultrasonic Power Supply

The digital ultrasonic generator converts the AC electrical power supply current into a high frequency, high voltage electrical signal. Through the digital ultrasonic generator, you can control the food cutting process by setting the related parameters, which is easy and intuitive. You can also integrate the generator parameters into your existing machine control panel so that all the parameters are in one panel for easy control and management.

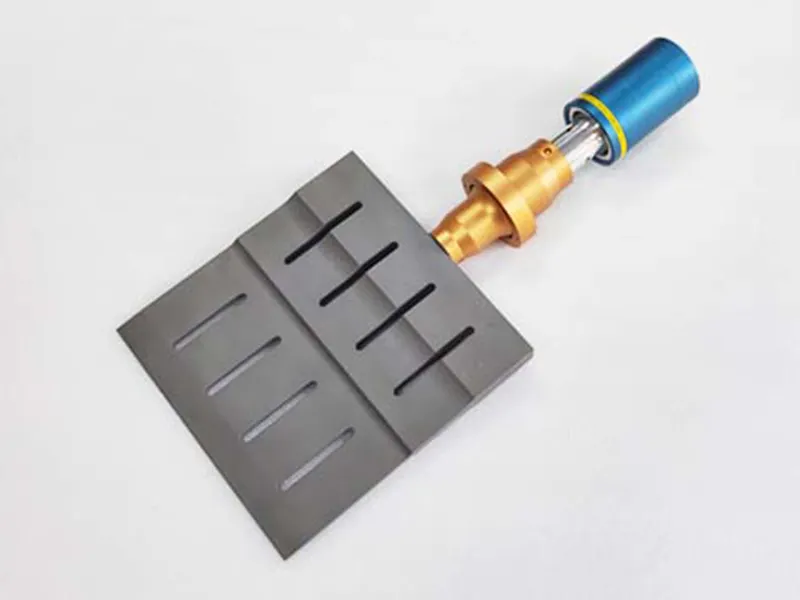

♦ CUTTING BLADE

Titanium Alloy Ultrasonic Cutting Blade

Food cutting blades are designed and manufactured through FEA analysis and are made of titanium alloy to ensure efficient and high-quality operation. The titanium alloy ultrasonic blade produces a virtually frictionless surface during cutting, minimizing sticking and deformation of the cut food.

Product parameters

|

Model |

KM-UFC20255 |

|

Frequency |

20KHz |

|

Power |

2000W |

|

Material of Blade |

Food industry approved Titanium |

|

Cutting Width |

255mm |

|

Cutting Height |

100mm |

|

Input AC |

110, 50/60Hz |

|

Generator |

Digital, Auto-tuning |

|

Cutter Type |

Full wave length ultrasonic food cutter |

|

Generator Weight |

5kg |

|

Transducer Weight |

3kg |

|

Blade Weight |

2kg |

|

Dimension of Generator(L*W*H) |

80mm*410mm*180mm |

Technical parameters for adapting blade types

|

Working Frequency |

20KHz 20KHz 20KHz 20KHz 20KHz |

|

Power |

2000W 2000W 2000W 2000W 2000W |

|

Cutting Width |

95mm 200mm 255mm 305mm 400mm |

|

Cutting Height |

60mm-185mm, customized(full wave or half wave optional) |

Adaptable knife type

Company Introduction

K&M Technologies Ltd. has occupied an important position in the market of ultrasonic fabric cutter. Our company has employed a dedicated manufacturing team. This team includes QC test technicians. They are committed to continuous improvement in product quality before delivery. Our service on ultrasonic fabric cutter production is very reliable among domestic and foreign customers. Welcome to visit our factory!

We hope to cooperate with you for a win-win situation and jointly create a better future.