KnMTech Ultrasonic Welding Metal to Plastic on Sale

Company Advantages

· KnMTech ultrasonic welding metal to plastic undergoes a overall assessment of product design to reduce the uncertainty of design.

· This product offers a versatile function and user-friendly operation.

· Our QC team monitor procedure as per quality system requirements.

Product Detail

Product description

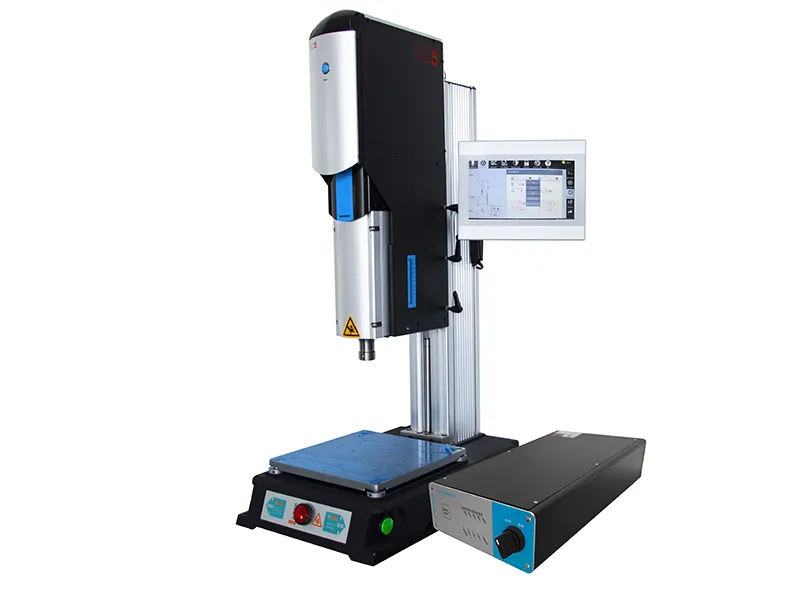

The new generation of DX5 ultrasonic plastic welding machines has many innovations: the streamlined profile frame gives it a good appearance; the timely controllability of the DX MAX servo action device gives it excellent welding controllability.

The servo control system as the core focus allows it to realize the selection of any starting point of the welding process; through the support of SOFTTOUCH mode, the sensitive weld structure of the plastic parts to be welded is taken care of when installing the ultrasonic welding horn; With two trigger modes: pressure and depth, and five welding mode: time, energy, ground, absolute depth, relative depth. The process-oriented operator control ensures super high availability; it is the best choice for your ultrasonic plastic welding machine at any time.

♦ STREAMLINED PROFILE

♦ EXCELLENT WELDING CONTROLLABILITY

The reinforced rigid structure and streamlined frame not only look beautiful but also make it convenient to control the up and down movement of the welding head. The installation of the servo motion device makes the welding process highly controllable. The welding head of the welding machine is equipped with LED lighting, which provides convenience for special application scenarios.

♦ FORCE AND SPEED

♦ WELDING FORCE SPEED CONTROL

Welding pressure and speed control: Real-time detection of depth, pressure, and speed process data feedback to the controller, through the controller's processing, the servo system is synchronized and adjusted by closed-loop control, which avoids the drawback of the transmission pneumatic welding method being unable to adjust the pressure and speed in real-time due to the influence of air source and inflation rate, as well as the traditional servo welding method through torque control cannot guarantee the synchronous adjustment of welding pressure and speed.

Product parameters

|

Frequency |

15kHz |

20kHz |

35kHz |

|

Power |

3200W |

3200W |

1500W |

|

Minimum/maximum welding force at 8 bar*[N]* |

50/3500 |

30/2500 |

20/1500 |

|

Working stroke (mm) |

100 |

||

|

Motion System |

Servo motor |

||

|

Trigger Mode |

Pressure, Depth |

||

|

Welding mode |

Time, Energy, Ground, Absolute Depth, Relative Depth |

||

|

Intelligent management |

Speed/Force/Amplitude/Quality/Data/Safety Management |

||

|

Amplitude Control |

Single amplitude/stepping amplitude |

||

|

Dimensions at maximum height |

650/1385/400mm |

||

|

Machine working radius to ultrasonic welding horn |

225mm |

||

|

Height Adjustment |

300mm |

||

|

Operation Panel |

10 inches touch screen panel |

||

|

Feature |

USB data export/welding record/data statistics |

||

|

Working rack |

Square column |

||

|

Language |

Chinese/ English |

||

|

Weldment parameter Recipe |

10 |

||

|

Stored welding counts |

99999 |

||

|

(welding process parameters) |

|||

|

Additional function control device (optional) |

Tooling clamping, X, and Y shifters, protective light curtains, film rollers, acoustic enclosure lift gates, etc |

||

Download

Company Features

· K&M Technologies Ltd. has been producing and offering high-quality ultrasonic welding metal to plastic for years. Our competence and experience in this industry are well-known.

· Located in an advantageous geographical position where is close to the ports, our factory offers convenient and fast transportation of goods, as well as shorten the delivery time.

· The service of KnMTech ranks top in ultrasonic welding metal to plastic industry. Contact us!

Product Details

K&M Technologies Ltd. strives excellent quality by attaching great importance to details in the production of ultrasonic welding metal to plastic.

Enterprise Advantages

Our company pays great attention to the construction of talent teams, because they are the basic element for our development. Therefore, we introduce and explore talented people regardless of regions and limitations in every possible way. Through giving full play to the potential, it promotes our company to develop efficiently.

K&M Technologies Ltd. has a professional service team to solve problems for customers.

With a focus on talents and techniques, our company holds our business philosophy of 'people-oriented, technological innovation, quality assurance'. We strive to give full play to the advantages of talents and adopt advanced technology, to produce a full range of products in high quality and reasonable price.

Our company was established in and has been engaged in the industry for years.

At the moment, our company's sales network has spread all over the country's major cities and regions. In the future, we will strive to open up a broader overseas market.