Factory Direct Ultrasonic Cake Cutting Machine Ultrasonic Cake Cutting Machine Company

Product details of the ultrasonic cake cutting machine

Product Introduction

KnMTech ultrasonic cake cutting machine is manufactured by using the technology that keeps up with advanced world standard. In the aspect of its quality, it has been tested for many times with the help of our professional team. K&M Technologies Ltd. will respect and meet your individual requirements.

Product Detail

Product description

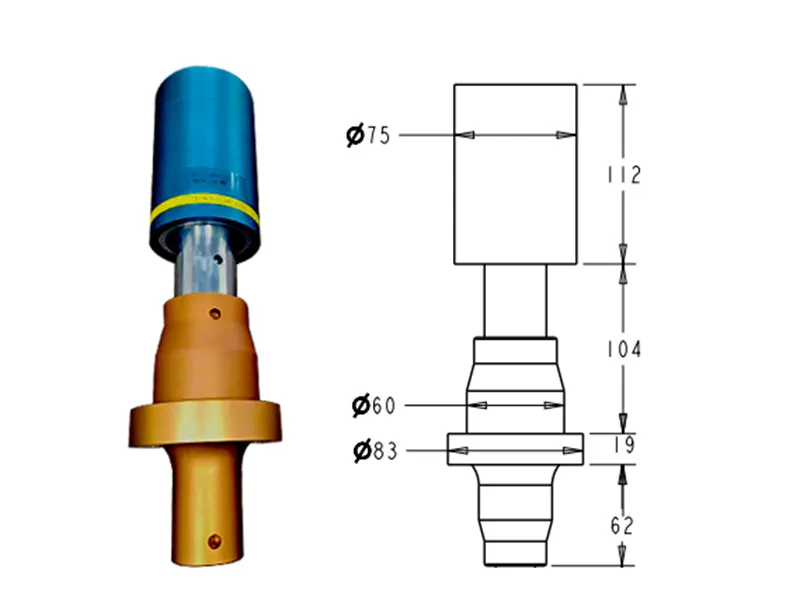

The ultrasonic food cutting system includes a generator, a converter, a booster, and a blade. The generator converts 50/60Hz AC line to high-frequency electrical energy, then transfers it to the converter, the converter uses its electromechanical features to convert the electrical energy into high-frequency vibration, then transfers the vibration to the booster, which can either raise or lower the amplitude of the blade’s mechanical motion depending on its design, then the booster transfers the vibration to the blade, which does the cutting process with high-frequency vibration. The ultrasonic food cutting system can be used in continuous cutting and can be integrated into manual food cutting machines or automated food cutting machines. Welcome to contact us for details!

Digital Ultrasonic Power Supply

The digital ultrasonic generator converts the AC electrical power supply current into a high frequency, high voltage electrical signal. The ultrasonic generator is available in 20,30,35,40KHz. Working amplitude is adjustable 10%-100% (1% accuracy). Through the digital ultrasonic generator, you can control the food cutting process by setting the related parameters. Easy and intuitive.

♦ CUTTING BLADE

Titanium Alloy Ultrasonic Cutting Blade

Food cutting blades are designed and manufactured through FEA analysis and are made of titanium alloy to ensure efficient and high-quality operation. The titanium alloy ultrasonic blade produces a virtually frictionless surface during cutting, minimizing sticking and deformation of the cut food.

Product parameters

|

Model |

KM-UFC20255 |

|

Frequency |

20KHz |

|

Power |

2000W |

|

Material of Blade |

Food industry approved Titanium |

|

Cutting Width |

255mm |

|

Cutting Height |

100mm |

|

Input AC |

110, 50/60Hz |

|

Generator |

Digital, Auto-tuning |

|

Cutter Type |

Full wave length ultrasonic food cutter |

|

Generator Weight |

5kg |

|

Transducer Weight |

3kg |

|

Blade Weight |

2kg |

|

Dimension of Generator(L*W*H) |

240mm*400mm*120mm |

Technical parameters for adapting blade types

|

Working Frequency |

20KHz 20KHz 20KHz 20KHz 20KHz |

|

Power |

2000W 2000W 2000W 2000W 2000W |

|

Cutting Width |

95mm 200mm 255mm 305mm 350mm |

|

Cutting Height |

60mm-260mm, customized(full wave or half wave optional) |

Adaptable knife type

Company Advantage

• Our company organizes a number of experienced and long-term professional technical personnel and management teams engaged in relevant fields. All this supplies favorable conditions for our development.

• The open and smooth traffic creates convenience for the transportation and timely supply of Ultrasonic Welding Machines,Filter Cartridge Making Machine,Ultrasonic Cutting Machine.

• Since the beginning in our company has been focusing on the development of Ultrasonic Welding Machines,Filter Cartridge Making Machine,Ultrasonic Cutting Machine. After years of research, we have achieved remarkable results in the management and management.

If you have any interest in K&M Technologies Ltd.'s Ultrasonic Welding Machines,Filter Cartridge Making Machine,Ultrasonic Cutting Machine, order now then you can enjoy discounts!