The Power Of Ultrasonic Generators: How They Revolutionize Industries

Welcome to the world of ultrasonic generators, where cutting-edge technology is revolutionizing industries across the globe. In this article, we will explore the incredible power of these advanced devices and how they are transforming manufacturing, healthcare, and more. Discover how ultrasonic generators are pushing boundaries and driving innovation like never before. Join us as we delve into the exciting world of ultrasonic technology and the endless possibilities it offers for the future.

- Introduction to Ultrasonic Generators

Ultrasonic generators have become an indispensable tool in various industries, revolutionizing the way businesses operate and the products they produce. In this article, we will delve into the world of ultrasonic generators, exploring their benefits, applications, and impact on industries worldwide.

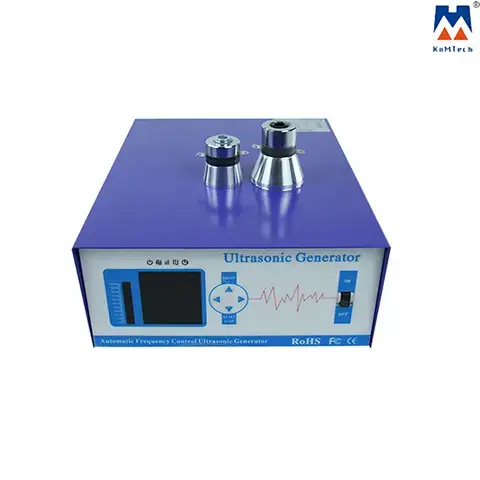

An ultrasonic generator is a device that produces high-frequency sound waves, typically above the range of human hearing. These sound waves are used for a variety of purposes, from cleaning and welding to cutting and sealing. The power of ultrasonic generators lies in their ability to generate intense vibrations that can be harnessed for various industrial processes.

One of the key benefits of ultrasonic generators is their efficiency. Unlike traditional methods that rely on heat or mechanical force, ultrasonic generators use sound waves to achieve results quickly and effectively. This not only saves time and energy but also reduces the risk of damage to delicate materials. In industries such as electronics manufacturing and medical device production, where precision is key, ultrasonic generators have proven to be a game-changer.

Another advantage of ultrasonic generators is their versatility. They can be used in a wide range of applications, from cleaning automotive parts to soldering electronic components. This versatility makes them a valuable tool for businesses looking to streamline their processes and improve product quality. In the food and beverage industry, for example, ultrasonic generators are used to emulsify liquids, homogenize mixtures, and extract flavors, all without the need for additives or preservatives.

Ultrasonic generators have also become an environmentally friendly option for industries seeking to reduce their carbon footprint. By using sound waves instead of harsh chemicals or excessive energy, businesses can minimize their impact on the environment while still achieving their production goals. This aligns with the growing trend towards sustainability in the corporate world, making ultrasonic generators a popular choice among forward-thinking companies.

In conclusion, ultrasonic generators are a powerful tool that has revolutionized industries around the world. Their efficiency, versatility, and eco-friendly benefits make them an attractive option for businesses looking to stay ahead of the curve. As technology continues to advance, we can expect to see even more innovative uses for ultrasonic generators in the years to come. Whether you work in manufacturing, healthcare, or any other industry, it's worth exploring the power of ultrasonic generators and the ways they can help your business thrive.

- Applications in Various Industries

Ultrasonic technology has long been recognized for its ability to revolutionize industries across the board. Ultrasonic generators, in particular, have proven to be a powerful tool in a wide variety of applications in various industries. From manufacturing to medical fields, the versatility and effectiveness of ultrasonic generators have transformed the way businesses operate and innovate.

In the manufacturing industry, ultrasonic generators are used for a myriad of applications such as welding, cutting, cleaning, and sieving. Ultrasonic welding, for example, utilizes high-frequency vibrations to bond materials together without the need for adhesives or solvents. This process is not only more efficient and cost-effective but also produces stronger and more precise bonds. Similarly, ultrasonic cutting technology allows for quick and precise cutting of materials such as plastics, fabrics, and food products. The high-frequency vibrations create clean and smooth cuts without any distortion or damage to the material, making it an ideal solution for industries that require precision cutting.

In the cleaning industry, ultrasonic generators are used for ultrasonic cleaning, which is a highly effective method for removing dirt, grease, and contaminants from a wide range of surfaces. The high-frequency vibrations create millions of tiny bubbles in the cleaning solution, which implode upon contact with the surface, dislodging and removing even the toughest grime. This technology is widely used in industries such as automotive, aerospace, and electronics, where cleanliness and precision are of utmost importance.

In the medical field, ultrasonic generators play a crucial role in imaging, diagnostics, and therapeutic applications. Ultrasound imaging, for example, uses high-frequency sound waves to create detailed images of internal organs and tissues, allowing healthcare professionals to diagnose and treat various medical conditions. Ultrasonic generators are also used in therapeutic ultrasound, where high-frequency vibrations are used to deliver targeted heat or mechanical energy to specific tissues, promoting healing and pain relief.

Beyond these industries, ultrasonic generators are also making a significant impact in agriculture, food processing, and environmental monitoring. In agriculture, ultrasonic generators are used for pest control, irrigation, and crop monitoring. In food processing, ultrasonic technology is used for food preservation, extraction, and quality control. In environmental monitoring, ultrasonic generators are used for air and water quality testing, as well as pollution control.

In conclusion, the power of ultrasonic generators cannot be overstated. Their versatility, efficiency, and effectiveness have transformed industries across the board, leading to improved processes, products, and outcomes. As technology continues to advance, the potential for ultrasonic generators to revolutionize even more industries is limitless.

- Advantages of Ultrasonic Technology

Ultrasonic technology has been making waves in various industries, revolutionizing the way tasks are carried out and providing countless advantages to businesses. Through the use of ultrasonic generators, companies can harness the power of this technology to improve efficiency, productivity, and overall performance.

One of the key advantages of ultrasonic technology is its precision. Ultrasonic generators are capable of producing high-frequency vibrations that can be precisely controlled to achieve the desired results. This level of precision is particularly important in industries such as manufacturing, where even the smallest error can have significant consequences. With ultrasonic technology, companies can ensure that their processes are carried out with utmost accuracy, leading to higher quality products and increased customer satisfaction.

Another advantage of ultrasonic generators is their versatility. These devices can be used in a wide range of applications, from cleaning and welding to cutting and sealing. This versatility makes them a valuable tool for businesses in various industries, as they can adapt the technology to suit their specific needs. For example, ultrasonic generators can be used in the food industry to clean equipment and remove contaminants, in the automotive industry for welding and cutting metal components, and in the medical industry for precision surgery.

In addition to precision and versatility, ultrasonic technology also offers efficiency benefits. Ultrasonic generators are energy-efficient and produce minimal waste, making them an environmentally friendly option for businesses looking to reduce their carbon footprint. By using ultrasonic technology, companies can lower their operating costs, increase production efficiency, and contribute to a more sustainable future.

Furthermore, ultrasonic generators are easy to use and maintain, requiring minimal training and upkeep. This means that businesses can quickly implement the technology into their operations without significant downtime or additional resources. The user-friendly nature of ultrasonic generators also allows for seamless integration with existing systems, further enhancing their appeal to businesses across various industries.

Overall, the power of ultrasonic generators lies in their ability to revolutionize industries by providing precision, versatility, efficiency, and ease of use. As businesses continue to seek ways to improve their processes and stay ahead of the competition, ultrasonic technology offers a powerful solution that can drive innovation and success. By harnessing the advantages of ultrasonic technology, companies can unlock new opportunities for growth and performance improvement, making it a valuable investment for the future.

- Impact on Efficiency and Quality

Ultrasonic generators have been making waves in various industries, revolutionizing the way they operate and boosting efficiency and quality along the way. These powerful devices have the ability to transform processes, streamline operations, and enhance overall output, making them invaluable tools for numerous sectors.

One of the key impacts of ultrasonic generators on efficiency lies in their ability to increase productivity. By using high-frequency sound waves to create vibrations, ultrasonic generators can effectively remove contaminants, debris, and unwanted materials from surfaces, leading to cleaner and more reliable results in a fraction of the time it would take using traditional methods. This not only speeds up production processes but also ensures a higher level of quality and consistency in the end product.

In the manufacturing industry, ultrasonic generators have been particularly game-changing. Whether it's for cleaning, welding, cutting, or sealing, these devices are able to perform tasks with unmatched precision and speed. For example, in welding applications, ultrasonic generators can create strong and durable bonds between materials without the use of adhesives or heat, resulting in clean and efficient joints that are less prone to defects. This not only saves time and money but also improves the overall quality of the final product.

Furthermore, the impact of ultrasonic generators on efficiency can also be seen in the healthcare sector. Ultrasonic cleaning systems, powered by ultrasonic generators, are widely used to sterilize medical instruments and equipment, ensuring the highest levels of hygiene and reducing the risk of contamination. By leveraging the power of ultrasonic technology, healthcare facilities can cut down on cleaning time, improve sterilization processes, and ultimately enhance patient safety and care.

In addition to efficiency, ultrasonic generators also have a significant impact on the quality of output in various industries. The precise control and focused energy of ultrasonic waves allow for meticulous and thorough cleaning, welding, and processing, resulting in products that meet the highest standards of excellence. Whether it's in the automotive industry, electronics manufacturing, or even food processing, the use of ultrasonic generators ensures that products are produced to exact specifications and are free from defects.

Overall, the power of ultrasonic generators cannot be underestimated. With their ability to enhance efficiency, improve quality, and optimize processes, these devices are truly revolutionizing industries across the board. From speeding up production lines to ensuring the highest levels of cleanliness and precision, ultrasonic generators are paving the way for a new era of innovation and advancement.

- Future Developments and Innovations

In recent years, ultrasonic generators have been making waves in various industries, revolutionizing the way processes are carried out and products are manufactured. These powerful devices have been at the forefront of technological advancements, offering new possibilities and capabilities that were previously unseen. As we look towards the future, there are several key developments and innovations in ultrasonic generator technology that are set to further transform industries across the board.

One of the most exciting developments in ultrasonic generator technology is the increasing miniaturization of these devices. As technology becomes more compact and portable, ultrasonic generators are now being incorporated into smaller and more versatile machines. This means that industries such as healthcare, automotive, and electronics can benefit from the power of ultrasonic technology in ways that were not possible before. For example, portable ultrasonic generators can now be used for on-the-go cleaning and sterilization in medical settings, or for precision welding in tight spaces in the automotive industry.

Another area of innovation in ultrasonic generator technology is the integration of artificial intelligence and automation. By incorporating AI algorithms into ultrasonic generators, industries can now benefit from more precise and efficient operations. For example, AI-powered ultrasonic generators can automatically adjust settings based on real-time data, leading to more consistent results and increased productivity. This level of automation not only saves time and labor costs but also ensures a higher quality end product.

Furthermore, advancements in materials science have also had a significant impact on the capabilities of ultrasonic generators. New materials that are better able to withstand intense ultrasonic vibrations have opened up new opportunities for industries to utilize this technology in ways that were previously not possible. For example, ultrasonic generators can now be used for cutting and shaping harder materials such as ceramics and composites, leading to more efficient manufacturing processes and higher quality products.

In addition, the integration of IoT (Internet of Things) technology with ultrasonic generators is set to revolutionize industries even further. By connecting ultrasonic generators to the internet, industries can now monitor and control these devices remotely, leading to increased efficiency and reduced downtime. This level of connectivity also allows for predictive maintenance, where issues can be detected and addressed before they cause any disruptions in production.

Overall, the future of ultrasonic generator technology looks bright, with new developments and innovations set to transform industries in ways we have never seen before. From miniaturization to AI integration to advancements in materials science and IoT connectivity, the possibilities are endless. Industries that embrace these technologies are set to gain a competitive edge and drive innovation in their respective fields. The power of ultrasonic generators is truly changing the game, and the future is looking brighter than ever.

Conclusion

In conclusion, the impact of ultrasonic generators on industries cannot be overstated. With 9 years of experience in the field, we have witnessed firsthand the revolutionary changes brought about by this technology. From increasing efficiency and precision in manufacturing processes to improving product quality and reducing waste, ultrasonic generators have truly transformed the way industries operate. As we look to the future, it is exciting to imagine the continued advancements and innovations that will be made possible by this powerful technology. The possibilities are endless, and the potential for growth and improvement across industries is truly inspiring. With ultrasonic generators leading the way, the future of industrial production looks brighter than ever.